Real cases

C1 - corrosive sulfur with DBDS (Qatar 2012)

Scenario

Chemical sector company , 4 step-up transformers

Technical specifications of transformers:

Manufacturer: Getra

Year: 2000

Power [MVA]: 47

Voltage [kV]: 34

Oil mass [kg]: 12,000

Oil type: Nynas Nitro 10 GBN

Solution

Solution: selective depolarisation treatment by Sea Marconi in on-load mode (transformer energised and under load throughout the entire treatment).

Treatment guaranteed DBDS < 10 mg/>g

| Before treatment | After treatment | |

|---|---|---|

| DBDS [mg/kg] | 125 | < 5d> |

| H2O [mg/kg] | 7 | 3 |

| TAN [mg KOH/g] | < 0,095d> | < 0,01d> |

| DF | 0.0190 | 0.0033 |

C1 - corrosive sulfur with DBDS (Chile 2012)

Scenario

Primary substation with 3 Grid transformers and 2 shunt reactors

Technical specifications of transformers:

Manufacturer: Zaporozhtransformator

Year: 1998

Power [MVA]: 250

Voltage [kV]: 345

Oil mass [kg]: 118,000

Oil type: Nynas naphthenic oil

Analytical and diagnostic results

Analysis and subsequent diagnosis performed by Sea Marconi on the machines of the customer showed a marked presence of DBDS

Solution

Solution: selective depolarisation treatment by Sea Marconi in both on-load and off-load modes.

Treatment guaranteed DBDS < 10 mg/>g

| Before treatment | After treatment | |

|---|---|---|

| DBDS [mg/kg] | 144 | < 10d> |

| H2O [mg/kg] | 16 | 5 |

| TAN [mg KOH/g] | < 0,01d> | < 0,01d> |

| DF | 0.0026 | 0.0015 |

C2 - corrosive sulfur without DBDS (Middle East 2009)

Scenario

Thermal power station with 8 step-up transformers(Middle East)

Technical specifications of transformers:

- Power [MVA]: 175

- Voltage [kV]: 400

- Oil type: SHELL Diala AX naphthenic oil

Step 1

The diagnoses of 2009 showed:

Total sulfur = 200

mg/kg

TCS (Total Corrosive Sulfur) = 157

mg/kg (DBDS eq.)

CCD Test = corrosive

IFT = 19

mN/m

DBTP = 38

mg/kg

Step 2

Breakdown in 2013

Step 3

Analysis after failure in progress ...

Step 4

Selective depolarisation (Chedcos) treatment recommended for the removal of sulfur compounds (NOT DBDS) responsible for corrosion.

C3 - corrosive sulfur from SDBP (Uruguay 2010)

Scenario

Uruguayan utility with transformers

October 2012: Breakdown two weeks after reclamation with Fuller's earth treatment(performed by local operator).

Technical specifications of transformer:

Transformer type: grid transformer with OLTC (on-load tap changer)

Manufacturer: Hitachi

Year: 1977

Power [MVA]: 425

Voltage [kV]: 500

Oil mass [kg]: 58,000

Oil type: YPF65 non-inhibited paraffinic oil

Analysis and diagnosis (by the owner)

Following field tests, the owner's diagnosis speculated a hugh energy discharge in the main casing. Subsequently, after laboratory tests, a f ailure emerged in the on-load tap changer which produced a discharge in the main casing.

Reclamation with Fuller's earth treatment rendered the oil aggressive towards the silver surfaces of the contacts.

Sea Marconi analysis, diagnosis and expertise

Columns with reactivated Fuller's earth (NOT used by Sea Marconi)

"At relatively high temperatures, sulfur-containing oil molecules may decompose and react with metal surface to form metal sulphides" (IEC 60422 Ed. 4 – 2013 art. 5.17)

«At relatively high temperatures, the oil molecules containing sulfur may decompose and react with metal surfaces, forming sulfides" (IEC 60422 Ed. 4-2013 art. 5.17)

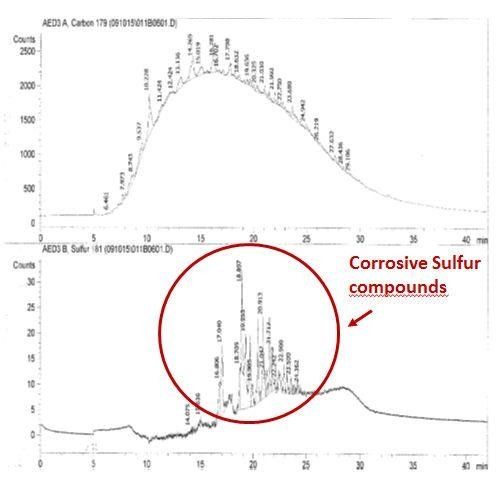

Sea Marconi classifies this case as C3 – corrosive sulfur from SDBP, which stands for sulfur deterioration by-products, i.e. corrosiveness caused by by-products of sulfur deterioration.

"The system for the regeneration of the oil used by the owner uses columns with Fuller's earth which are reactivated by "uncontrolled" combustion. Because of the high temperatures, the sulfur compounds (dibenzothiophene, etc.) naturally present in oil – together with the interaction with additives (DBDS, etc.) – decompose into by-products of sulfur deterioration (SDBPs such as H2S, mercaptans, etc. with corrosive properties) forming sulfides such as as CuS, Cu2S, Ag 2S, etc.". Ref. other real cases of National Grid, ABB, etc.

| Analytical results | |

|---|---|

| CCD | Corrosive |

| TCS DBDS Eq. [mg/kg] | 131 |

| ASTM 1275 B | 4C |

| DBTP [mg/kg] | 24 |

| TAN [mg KOH/g] | 0.01 |

| DF | 0.018 |

| IFT [mN/m] | 0.018 |