Pre-energisation

" Pre-energisation" refers to the phase that includes activities prior to energisation of the transformer and therefore mainly activities of installation of equipment at the final site and filling with purchased and accepted oil.

In detail, when the transformer reaches its operating site, a series of activities is performed that fall under the name of installation or commissioning; for example, recorded logs are read by sensors during transportation of the transformer, the dew point is monitored to provide guidance on the moisture inside the casing (typically < 20 °C), dopodiché si procede al montaggio degli accessori, alle connessioni elettriche, ai sistemi antincendio, ai sistemi di protezione ambientale, alle integrazione di sistema, ed al filled with oil that has been selected and accepted).

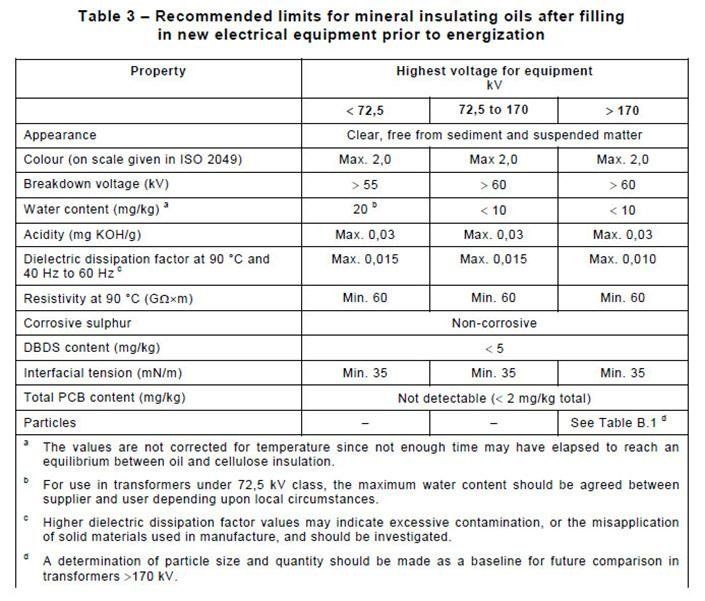

The filling is an extremely delicate operation that requires the intervention of qualified experts and the use of appropriate operating procedures, with suitably trained personnel and state of the art plant equipment. In concrete terms, the first step is to place the transformer under vacuum, then proceed with the filling with the new insulating oil, and then moving on to treatment of the oil until the contaminants reach the thresholds set out in relation to regulatory, technical and contractual conditions (see pre-energisation table, IEC 60422).

IEC 60422 and 4 2013 – Table 3 - Recommended limits for mineral insulating oils after filling in new electrical equipment prior to energisation

In this phase, Sea Marconi is able to support owners in the supervision and installationof the oil-transformer system(and of its accessories).

In concrete terms, Sea Marconi performs:

- A. sampling, analysisof oil, and certification of analytical results. The type of controls vary based on the type of machine-oil and the critical issue diagnosed;

- B. diagnosis of critical problemsin the oil-transformer system; In particular, the absence must be verified of critical issues related to transportation and cross-contamination between the oil purchased (and accepted) and the oil of impregnation used for factory tests, at risk of contamination due to the use of low quality oils and of improperly washed treatment systems. It should be noted that 10/15% of the oil used for the tests (even after emptying) remains impregnated in the solid insulation, and is deposited in the form of films on the inner surfaces of the transformer, the bottom of the casing and in the dead points of radiators.

- C. a final reportsuggesting appropriate corrective actions( solutions) to eliminate or mitigate the critical problems found. Particularly important corrective actions include interventions on the oil (filling of the transformer, physical treatment, selective depolarisation, and integrated treatment of the oil-transformer system) as well as electromechanical activities on the machine.

?

Do you know the correct procedures for vacuum filling? And for the next treatment?

Contact us for performing the activity or for simple advice

?

Do you want to verify that the oil just pumped into the transformer complies with regulatory parameters?

Contact us for a targeted quotation

Why to choose Sea Marconi

- Sea Marconi has developed the sector's largest private database with over 70,000 devices and 240,000 diagnoses.

- Accredited and state of the art analyses are performed. In 2017 alone, 17,500 samples of insulating oil from about 10,000 transformers were analysed.

- Equipped with a full field kit set to obtain a first screening of oil directly in the field (screening of PCBs, acidity and total corrosive sulfur)

Normative requirements

IEC 60422 ed. 4.0 - 2013-> Mineral insulating oils in electrical equipment – Supervision and maintenance guidance