Operation

The " Operation" phase has a time span ranging from 2-3 years to 20-25 years of life of the transformer in relation to the load profile, thermal life consumed, and supervision and maintenance practices.

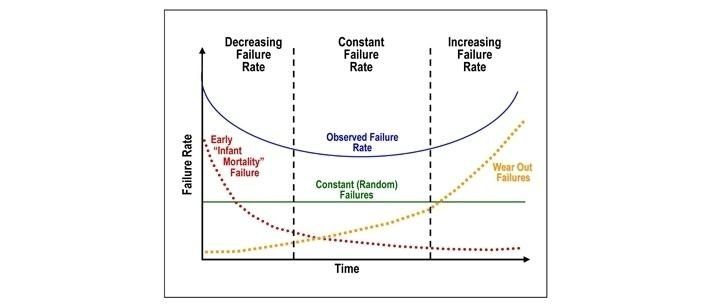

Some critical problems caused by high load profiles, poor maintenance or external influences may occur in this phase. In the central part of the operating phase, the failure rate is constant, but in the terminal phase failures increase due to normal deterioration of the oil-transformer system.

In this phase, Sea Marconi is able to support owners in supervision and maintenance of the oil-transformer system (and of its accessories).

In concrete terms, Sea Marconi performs:

- A. activities of sampling, analysisof oil, and certification of analytical results. The type and frequency of controls vary based on the type of machine-oil and the critical problem diagnosed;

- B. diagnosis of critical problemsin the oil-transformer system. In particular, it is necessary to monitor the transformer with constant regularity, assessing the trends of the main parameters of the oil also and especially in the light of the expected behaviour of the transformer, which Sea Marconi is able to define more clearly thanks to the experience collected in the sector's largest independent private database;

- C. a final reportsuggesting appropriate corrective actions( solutions) for eliminating or mitigating the critical problems found. Particularly important corrective actions are interventions on oil (physical treatment, selective depolarisation selective, PVB dehalogenation and integrated treatment of the oil-transformer system), as well as electromechanical activities on machinery.

? Have you already checked that your oil does not have a critical "corrosive sulfur" problem?

Contact us to check it or click here to learn more

? Acidity of oil is a symptom of aging of insulating oil. This critical problem can be overcome without changing the oil, through selective depolarisation treatment.

Contact us to learn about operational procedures and guarantees for treatment

Why to choose Sea Marconi

- Sea Marconi has developed the sector's largest private database. In 2017 alone, about 10,000transformers (and other equipment with fluid insulation) were analysed, most of which in their "in-service" phase.

- Sea Marconi performs accredited and state of the art analyses; this means that for mineral insulating oils, we can not only perform all the tests prescribed by sector standards, but also those based on the specific problems of the customer (e.g. SF6 in oil, corrosion problems) not yet covered by sector standards.

- Sea Marconi conceives, designs and produces in-house the decontamination unit (MDU) that is used daily for the different treatments of oils and transformers all over the world (directly or through local partners). Technologies, processes and materials (patented) used have allowed one of the treatments, dehalogenation of PCBs in oil, to be ranked as the Best Available Technique (BAT) by the Italian Ministry of the Environment (Min. Decree 29/01/2007 – O.J. No. 133 of 07/06/2007)

Normative requirements

IEC 60422 ed. 4.0 - 2013-> Mineral insulating oils in electrical equipment - Supervision and maintenance guidance

IEC 60599 ed. 2.0 - 1999-> Mineral oil-impregnated electrical equipment in service – Guide to the interpretation of dissolved and free gases analysis