Oil replacement

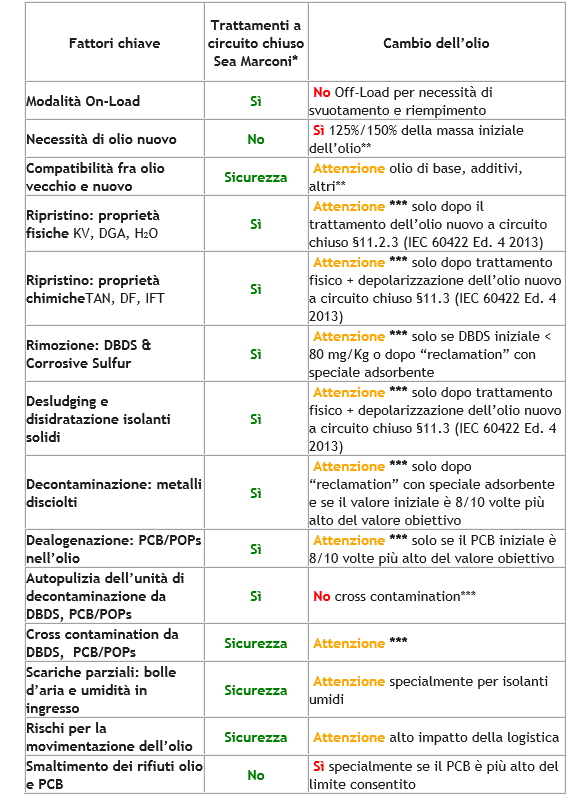

Sea Marconi's typical approach is to avoid replacement of a deteriorated oil, preferring its treatment (in a manner similar to dialysis) to restore it to "as new" condition and at the same time also "clean" the transformer. The treatments (with respect to oil change) are economically more advantageous, avoid the risks associated with the handling of huge amounts of oil and protect the environment because they avoid the disposal of a resource (insulating oil) that is still usable.

When the oil is in a very advanced state of deterioration or when treatment is not convenient from an economic point of view, Sea Marconi can also change the oil load. This operation has several phases and many critical issues: logistical, functional and environmental, so it is always good to rely on a professional and competent operator.

"Sea Marconi solutions" vs "Change of oil load"

* Integrated treatments with MDUs (Mobile Decontamination Units) using closed-loop processes patented by Sea Marconi

** In line with IEC 60296 Ed. 4, 2012

*** Because old oil remains impregnated mainly in insulating solids

1. Emptying

In particular, utmost attention must be paid to the activity of emptying the transformer, which leads to a vacuum in the casing (where possible), but strictly complying with the operating protocols of the machine's manufacturer or the customer.

2. Treatment and filling

It should be known that the new oil, depending on the transformer in which it will be used, should be treated both when it is still in the tank and after it is placed in the transformer. In addition to responding to regulatory requirements, this operation is necessary in order to ensure that the new oil is not contaminated by the oil residue (cross-contamination) that remains impregnated in the inner parts of the transformer and accounts for about 15% of the total quantity.

Sea Marconi performs these activities with absolute professionalism respecting sectoral guidelines and the most stringent safety standards of the customer. The following are the main phases:

- Transport, installation and connection of the treatment equipment

- Initial analytical controls

- Emptying the transformer

- Filling the transformer

- New oil treatment

- Checking levels and vents

- Replacing salt driers with silica gel

- Analytical controls at the end of intervention

- Removal and transport of the treatment units and tanks