Sustainable solutions for Life Cycle Management (LCM)

of electrical transformers with insulating fluids

Depolarisation against corrosive sulfur

For insulating fluids with critical problems of corrosive sulfur (presence of DBDS > 10 mg/kg), Sea Marconi has developed and patented Chedcos® selective depolarisation from corrosive sulfur, an integrated solution that has been validated with success on the market.

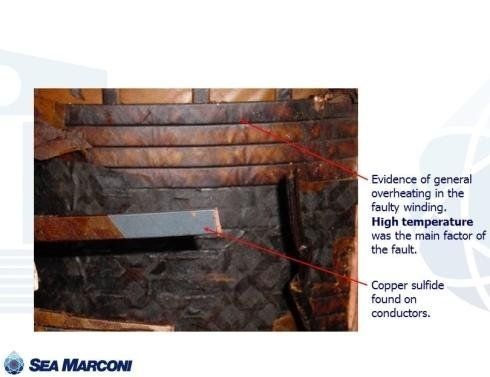

In July 2005, Sea Marconi pioneered discovery of DBDS (dibenzyl disulfide) as a cause of catastrophic failure due to corrosive sulfur. The DBDS present in contaminated fluids reacts with the copper inside the equipment forming copper sulfide; this conductive compound is deposited on the pressboards reducing their insulation up to the point of provoking the electric arc and failure, with consequent direct damage (loss of machine) and indirect damage (loss of production).

Together with the discovery of DBDS, Sea Marconi developed Chedcos selective depolarisation ®

. This oil treatment is effective, economic and definitive because it eliminates the cause of the problem (DBDS < di 10 mg/>g) and guarantees functional properties in conformity with IEC 60422 Ed. 4-2012, CIGRE 378-2009 Art. 4.2.

Selective depolarisation uses

- Sea Marconi's MDUs

- selective reagents (S/CHED®)

- safe operating procedures for activities on-site with closed loop, also "On-Load".

Chedcos® offers the advantage of avoiding the critical issues related to operational fluid replacement, which would still be contaminated by the DBDS in the oil that remains impregnated in the pressboards.

Case records of failure, also reported by CIGRE 378, show that even the passivator(e.g. Irgamet 39) does not eliminate the cause of corrosion (DBDS), and furthermore is destined to lose effectiveness over time while its protective action on copper surfaces is uneven and ineffective.

Sea Marconi experience

Total figure for equipment decontaminated from corrosive sulfur up to December 2017 500 (figure recorded in December 2017)

Total oil mass of oil decontaminated from corrosive sulfur up to December 2017 approx. 7,736 tonnes

In addition to responding effectively to cases of corrosiveness by DBDS ( C1 ), Chedcos® selective depolarisation is also able to offer a solution to cases of corrosiveness caused by other sulfur compounds ( C2 ), by by-products of deterioration of sulfur ( C3 ) or by metals dissolved in the oil ( C4 ).

In these cases, before planning selective depolarisation on the machine with corrosive oil, tests are performed at laboratory level; on-site decontamination takes place only in the case where there is the certainty of eliminating the cause of corrosiveness.

C3 - Corrosione da sottoprodotti di degrado dello zolfo (SDBP)

Il reagente è indispensabile per eliminare i composti corrosivi dello zolfo

Inserisci il titolo qui

Thank you for contacting us.

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Life cycle Management

What to monitor and when

Contact us

Contact us

Thank you for contacting us.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Solutions

Sea Marconi (Chedcos) Solution

Critical issues

Corrosive oil

Contact us

Thank you for contacting us.

We will get back to you as soon as possible

.

Oops, there was an error sending your message.

Please try again later

.

Treatments of insulating oils and transformers

Contact us

Thank you for contacting us.

We will get back to you as soon as possible

.

Oops, there was an error sending your message.

Please try again later

.